Description

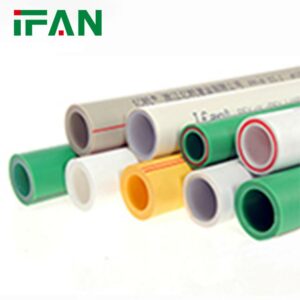

Grey Color PPR Material PPR Pipe

| PN 12.5 | PN 16 | PN 20 | PN 25 |

| Size(mm) | Size(mm) | Size(mm) | Size(mm) |

| 20X2.0 | 20X2.3 | 20X2.8 | 20X3.4 |

| 25X2.3 | 25X2.8 | 25X3.5 | 25X4.2 |

| 32X3.0 | 32X3.6 | 32X4.4 | 32X5.4 |

| 40X3.7 | 40X4.5 | 40X5.5 | 40X6.7 |

| 50X4.6 | 50X5.6 | 50X6.9 | 50X8.4 |

| 63X5.8 | 63X7.1 | 63X8.7 | 63X10.5 |

| 75X6.9 | 75X8.4 | 75X10.1 | 75X12.5 |

| 90X8.2 | 90X10.0 | 90X12.3 | 90X15.0 |

| 110X10.0 | 110X12.1 | 110X15.1 | 110X18.3 |

| 125X11.4 | 125X13.8 | 125X17.4 | 125X20.8 |

| 160X14.6 | 160X17.8 | 160X21.6 | 160X26.6 |

Raw material:

PPR is a random copolymer polypropylene synthesized by the gas phase method (PP and PE). Its structural characteristics are that PE molecules are irregularly linked in PP molecules, with molecular weight ranging from 300,000 to 800,000. The pipe produced by using PPR raw materials is also called random copolymerization polypropylene pipe, which is a plastic pipe product developed and applied in the late 1980s and early 1990s. With its excellent performance and a wide range of applications, it has occupied a place in the plastic pipe market and is recognized as a green environmental protection product. However, in recent years, the market operation, the above analysis examples of PPR plastic pipe quality problems and found that there are many problems in the market of PPR pipe, these problems to a large extent restricted the benign development of PPR pipe.

Tips for buying:

Having just bought a new house, many people are busy decorating their love nest. How to choose the right pipe at the right price is a very important thing for them. Here are a few tips on how to tell a good PPR tube from a bad one.

1. “Touch” : whether the texture is exquisite and whether the particles are even. PPR tubes on the market are mainly white, gray and green. Under normal circumstances, recycled plastic cannot be white, so many people often think that white is the best, in fact, this view is one-sided. With the improvement of technology, color is not the standard to distinguish between good and bad PPR tubes. Tube is good or bad, look is not able to solve the problem, touch, coarse particles are likely to be mixed with other impurities.

2. “Smell” : there is no smell. The main material of PPR pipe is polypropylene. Good pipe has no smell, and poor pipe has a strange taste. It is likely to be mixed with polyethylene (PE), rather than polypropylene.

3. “Pinch” : PPR tube has considerable hardness, casually can pinch into deformation tube, certainly not PPR tube.

4. “Smash” : good PPR tube, “resilience” is good, too easy to smash calcium carbonate filler is too much, naturally not a good PPR tube. Smashing the PPR tube is not necessarily a good tube, the key is to look at the raw materials and processing technology.

5. “Burn” : Fire a fire, very intuitive and very useful. PPR tubes mixed with recycled plastic and other impurities can smoke black and have a pungent smell; Good material after burning not only will not take black smoke, no smell, after burning, the liquid is still very clean.

6. According to the national testing standards, some simple testing items can be identified through the senses.

Related products

-

Uncategorized

IFANPLUS PPR PIPE FITTINGS

-

PPR

IFAN PPR Pipes

-

PPR Pipe

Green PPR Pipe