Description

PPR elbows are essential components in piping systems, made from polypropylene random copolymer (PPR). They serve a critical role in directing the flow of fluids by changing the direction of the pipes. This introduction provides a detailed overview of PPR elbows, including their features, advantages, applications, and installation methods.

Product Overview

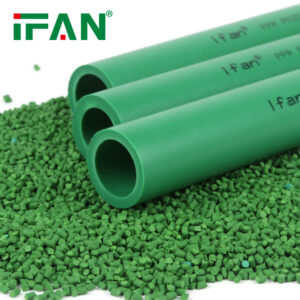

PPR elbows are fittings designed to connect two sections of pipe and alter the direction of the flow. These elbows typically come in 45-degree and 90-degree angles, though custom angles are available. Made from PPR material, these fittings offer a combination of durability and flexibility. The PPR material provides resistance to corrosion, high temperatures, and various chemicals.

Example: In a home plumbing system, a 90-degree PPR elbow helps to navigate pipes around a corner, ensuring the water flows smoothly through the system.

Material Properties

PPR elbows are manufactured from polypropylene random copolymer (PPR), known for its strength and versatility. PPR material offers several benefits, including high impact resistance, low thermal conductivity, and excellent chemical resistance. This makes PPR elbows suitable for a wide range of applications.

Example: PPR elbows can withstand hot water temperatures in residential heating systems and are resistant to chemicals in industrial applications.

Advantages of PPR Elbows

- Durability: PPR elbows resist impact and pressure, ensuring a long service life. They do not corrode or rust, unlike metal fittings.

- Temperature Resistance: They handle temperatures up to 95°C (203°F) without deforming, making them suitable for hot water applications.

- Chemical Resistance: PPR elbows resist a broad range of chemicals, including acids and alkalis, making them versatile for various industries.

- Lightweight: Compared to metal fittings, PPR elbows are lighter, which simplifies handling and installation.

- Ease of Installation: They use heat fusion or socket fusion techniques, making them easy to install and reducing the risk of leaks.

Example: In an industrial setup dealing with acidic or alkaline fluids, PPR elbows provide a reliable connection without the risk of corrosion.

Applications

PPR elbows are used in various applications, including residential, commercial, and industrial systems. They are commonly found in water supply, heating systems, and chemical transport pipelines.

- Residential Plumbing: PPR elbows help direct water flow around obstacles in home plumbing systems.

- Commercial Buildings: They are used in the plumbing systems of commercial buildings to manage water distribution.

- Industrial Processes: PPR elbows are used in chemical processing and other industrial applications due to their chemical resistance and durability.

Example: In a large commercial building, PPR elbows manage the water distribution system, allowing pipes to navigate around structural elements.

Installation Methods

Installing PPR elbows typically involves either heat fusion or socket fusion techniques.

- Heat Fusion: This method involves heating the ends of the pipes and elbows until they melt. The heated components are then joined together, forming a strong, seamless connection once cooled.

- Socket Fusion: This technique involves heating the inside of the elbow and the outside of the pipe simultaneously. The components are then pushed together, allowing them to fuse into a solid joint.

Example: For a residential water supply system, heat fusion provides a secure and leak-proof connection between PPR elbows and pipes.

Maintenance and Care

Maintaining PPR elbows is relatively straightforward. Regular inspections can help detect any signs of wear or damage. While PPR elbows are resistant to most chemicals and environmental factors, avoiding exposure to extreme temperatures or aggressive chemicals will prolong their lifespan.

Example: In a heating system, regularly checking the connections for leaks ensures that the PPR elbows continue to function effectively.

Environmental Impact

PPR elbows are environmentally friendly due to their recyclable nature. The production and disposal processes have a lower environmental impact compared to metal fittings. Additionally, PPR materials are free from harmful substances, contributing to safer environmental practices.

Example: When renovating a plumbing system, using PPR elbows can reduce environmental impact compared to using traditional metal fittings.

Conclusion

PPR elbows play a vital role in modern piping systems, offering durability, flexibility, and resistance to a wide range of environmental factors. Their applications span residential, commercial, and industrial settings, providing reliable solutions for managing fluid flow. By understanding their features, advantages, and installation methods, users can make informed decisions and ensure the effective performance of their piping systems.

Connect

IFAN factory started in 1993. And IFAN has workshop 120000 square meter with 610 staff. IFAN can design and produce all plumbing pipe and fitting include PPR,PVC,CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting ,brass fitting, brass ball valve ,heating system , gas system , sanitary faucets and hose, In the past 30 Years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory use best materials to produce high quality pipe and fittings with automatic production line and high tech quality control machines. The most important,IFAN can guarantee that all pipes and fittings manufactured by IFAN are qualified. More information pls feel free contact us Whatsapp.

Related products

-

PPR

PPR Fittings

-

PPR

PPR Pipe