Description

Proper installation of PPR (Polypropylene Random Copolymer) fittings is crucial to ensure leak-free plumbing systems. This guide outlines the step-by-step techniques required for successful installation, along with practical examples and comprehensive information.

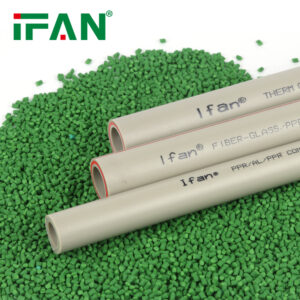

Understanding PPR Fittings

PPR fittings are designed for use in both hot and cold water plumbing systems due to their high temperature resistance and durability. They come in various types, including elbows, tees, couplings, and reducers, each serving specific connection needs.

Preparation and Tools

Before starting installation, gather the necessary tools and materials:

Tools: Pipe cutter, chamfering tool, measuring tape.

Materials: PPR pipes, fittings, marker pen, and a clean cloth for wiping.

Step-by-Step Installation Process

1.Cutting the PPR Pipe:

Measure and mark the pipe to the required length using a marker pen.

Use a pipe cutter to make a straight and clean cut. Ensure the cut is perpendicular to the pipe axis to avoid leaks.

2.Chamfering the Pipe:

Use a chamfering tool to remove burrs and sharp edges from the pipe end.

This step ensures a smooth surface for proper insertion into the PPR fitting, preventing damage to the sealing ring.

3.Assembling the Fitting:

Ensure the fitting and pipe are clean and free of dust or debris.

Insert the pipe into the fitting until it reaches the stop inside. Make sure it is fully seated to ensure a secure connection.

4.Marking Depth:

Use a marker to indicate the insertion depth of the pipe into the fitting.

This marking ensures consistency and accuracy during the assembly process.

5.Heating and Welding:

Heat both the pipe end and the fitting socket using an appropriate PPR welding device.

Maintain the correct welding temperature and apply slight pressure to the pipe during insertion to achieve a proper fusion.

6.Cooling and Testing:

Allow the welded joint to cool naturally without moving the pipe.

Once cooled, perform a pressure test to ensure the joint is leak-free and secure.

Common Installation Challenges and Solutions

Improper Cutting: Ensure precise cuts using a pipe cutter to prevent uneven edges that could compromise sealing.

Insufficient Heating: Properly heat both the pipe and fitting to ensure adequate fusion and strength of the joint.

Incorrect Depth Insertion: Always mark and check the insertion depth to ensure a tight and secure fit.

Example Application: Residential Plumbing

For instance, in residential plumbing, PPR fittings are commonly used to connect water supply lines to fixtures such as sinks and showers. The reliable installation techniques ensure long-term performance and minimal maintenance.

Conclusion

Mastering the installation techniques for PPR fittings is essential for achieving reliable and durable plumbing systems. By following these step-by-step guidelines and addressing common challenges effectively, professionals and DIY enthusiasts can ensure leak-free connections that meet industry standards and customer expectations.

By adhering to proper installation practices and utilizing the right tools and materials, plumbing systems equipped with PPR fittings can deliver efficient water distribution and contribute to sustainable building practices.

Connect

IFAN factory started in 1993. And IFAN has workshop 120000 square meter with 610 staff. IFAN can design and produce all plumbing pipe and fitting include PPR,PVC,CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting ,brass fitting, brass ball valve ,heating system , gas system , sanitary faucets and hose, In the past 30 Years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory use best materials to produce high quality pipe and fittings with automatic production line and high tech quality control machines. The most important,IFAN can guarantee that all pipes and fittings manufactured by IFAN are qualified. More information pls feel free contact us Whatsapp.

Related products